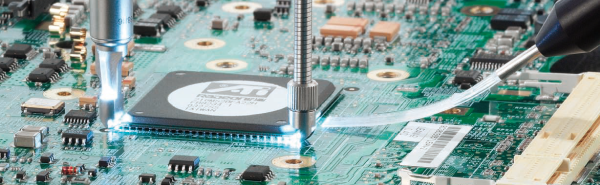

Albacomp EA Ltd. has considerable experience in the field of lead-free BGA assembly. In addition to the knowledge, we have the necessary technology as well, so we are producing not only in high quality but with our Ersascope, we are able to verify the quality of the placement, and thanks to our Pace ThermoFIo rework station, we undertake sealing, re-soldering and reballing as well.

Our technologies

Please refer for our placement technology to the SMT Production page.

Ersascope 2

The standard for planting BGA integrated circuits (IPC-7095B) proposes to use the endoscope for tests.

Although according to the feedbacks, we believe that we can assembly BGA in high quality, in fact, the proliferation of the lead-free technology has brought about new problems, which the usual testing methods cannot detect.

The Ersascope 2 type endoscope is designed specifically for soldering faults exploration of BGA, CSP and Flip Chip circuits and can reveal such important details, even the most advanced scanning equipment is no capable of.

The BGA IC testing allows us to change the heat profile of the reflow oven if we consider it necessary based on the test, so we could produce the best possible quality.

Pace ThermoFlo rework station

Using our rework station, we can safely remove or plant a wide range of SMD components (e.g. CSP, FC, PBGA, CBGA, MLF, LCC). Every operation, so the removing, positioning replacing, and re-soldering of the component are carried out along a single axis, thus eliminating the shifting of the component.

Request for Quotation

If you are looking for a professional manufacturer partner, please contact us by filling out our simple RFQ form.